Public Time :2023-2-4 6:42:52

[|

A |

]

China, February 4, 2023 – As the domestic economy gradually recovers, large-scale engineering projects in sectors such as petroleum and chemicals have commenced construction one after another. Universal Valves Group has recently delivered a batch of new energy-saving desuperheating and pressure reducing devices to the construction site of a major chemical group. Workers are busy and orderly engaged in the installation, welding, and commissioning of these units.

What are the technical advantages of the new energy-saving desuperheating and pressure reducing devices developed and manufactured by Universal Valves Group?

These specialized devices are used in industrial steam pipeline systems to reduce the temperature and pressure of primary high-temperature, high-pressure steam, ensuring that the secondary steam at the outlet meets the pressure and temperature values required by the production process.

Structural Features of the New Energy-Saving Desuperheating and Pressure Reducing Device:

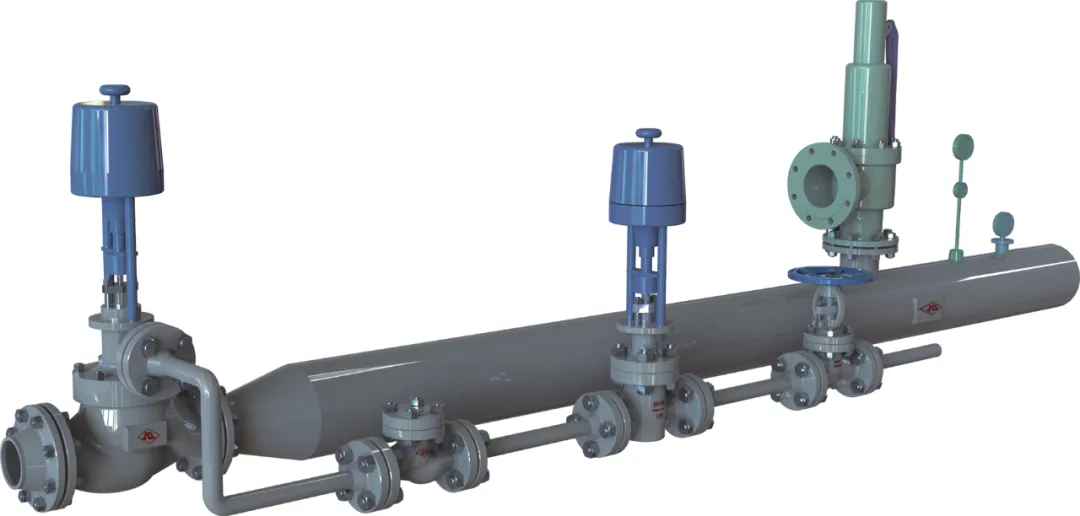

The HQWY series desuperheating and pressure reducing device is a new generation of environmentally friendly energy product developed by Universal Valves Group. It incorporates advanced domestic and international structures and technologies for desuperheating and pressure reduction, combined with over two decades of production experience and practical data. The device consists of four main components: the desuperheating and pressure reducing valve, steam pipeline, desuperheating water pipeline, and control system.

1. Desuperheating and Pressure Reducing Valve

(1) High-temperature, high-pressure steam undergoes simultaneous pressure reduction and temperature reduction within a single valve body, enabling self-regulating steam control.

(2) The pressure reduction component features a multi-hole cage-type noise-reducing structure with a flow balance cover to ensure stable operation of the outlet steam.

(3) The number of pressure reduction stages is determined by the pressure difference between the inlet and outlet, with each stage’s pressure drop strictly calculated to avoid stick flowing, thereby reducing wear on the throttling components and minimizing vibration and noise from high-speed steam flow.

(4) Temperature reduction is achieved by a desuperheating device inside the valve. Desuperheating water is sprayed through an automatically adjustable atomizing nozzle, instantly mixing with the high-speed steam to rapidly reduce its temperature. This prevents the formation of water droplets in the pipeline, protecting the valve and pipeline inner walls and achieving optimal desuperheating effort.

(5) The nozzle’s water injection volume adjusts synchronously with changes in steam load, ensuring sufficient spray velocity and improving atomization effort compared to fixed nozzles. This makes it suitable for lower steam loads.

(6) The valve seat employs a single-seat structure, reducing leakage compared to double-seat designs. The throttling holes on the pressure reduction component are arranged linearly, enabling continuous and stable adjustment (0-100%) when the valve disc is lifted, ensuring accuracy and precision in regulation.

(7) The valve integrates pressure reduction, temperature reduction, and noise reduction functions into a single unit, significantly reducing the footprint of the original system.

2. Steam Pipeline

(1) The use of the desuperheating and pressure reducing valve eliminates the need for a separate mixing pipeline for water spray desuperheating, reducing the overall device length by approximately half. This compact design saves space and reduces engineering costs.

(2) The pipeline is equipped with safety valves, pressure gauges, thermometers, and other instruments to ensure safe operation.

3. Desuperheating Water System

(1) The desuperheating system consists of a desuperheating water control valve, check valve, shut-off valve, filter, and desuperheating water pipeline.

(2) The desuperheating water control valve features a cage sleeve structure or a high-pressure differential labyrinth disc structure, capable of withstanding high pressure differences and stably controlling the desuperheating water flow.

(3) The valve seat uses a single-seal structure, preventing excessive leakage and instability when the valve is closed or at low openings.

(4) Control valves of the same caliber offer different CV values to ensure precision and sensitivity in regulation.

4. Thermal Regulation Device

(1) The control system comprises an automatic control cabinet (or DCS system) and an electric actuator.

(2) The control method can be customized based on order requirements. The automatic control cabinet instruments include: inlet temperature display, inlet pressure display, outlet temperature regulator, outlet pressure regulator, and alarm devices.

(3) Steam pressure regulation is achieved by measuring pressure via an on-site pressure transmitter, converting steam pressure into a 4-20mA current signal. The regulator then transmits the signal to the electric actuator, which adjusts the desuperheating and pressure reducing valve to achieve pressure regulation.

(4) Steam temperature regulation is achieved by transmitting temperature signals from an on-site thermal resistor (thermocouple) to the regulator. The regulator automatically calculates the valve opening based on preset programs and sends the signal to the electric actuator, which adjusts the desuperheating water control valve to regulate water flow and achieve temperature reduction.

Huanqiu Valves Group is a national high-tech enterprise, with its Technical Innovation Center recognized as a provincial-level enterprise technology center. The group has developed 36 types of high-tech products that serve as domestic substitutes for imported technologies, including power station turbine bypass system valves, high/low bypass devices, desuperheating and pressure reducing devices, control valves, quick-closing steam extraction check valves for thermal power plants, and quick-closing butterfly valves. The group holds national special equipment production licenses and relevant qualifications for manufacturing desuperheating and pressure reducing devices. With advanced modern production and testing equipment, it provides valve products that meet various complex working conditions, including high temperature, high pressure, sulfur resistance, low temperature, corrosion resistance, and erosion resistance. The group enjoys significant brand recognition and reputation in the power, petroleum, and petrochemical industries.